Concrete has been used in construction since time immemorial. In the concrete construction industry there are various sorts of concrete available. They are as follows:

Modern concrete, High-strength concrete, Stamped concrete, High-performance concrete, Ultra high-performance concrete, Micro-reinforced ultra-high-performance concrete, Self-consolidating concrete, Vacuum concrete, Shotcrete, Limecrete, Pervious concrete, Cellular concrete, Roller-compacted concrete, Glass concrete, Asphalt concrete, Rapid strength concrete, Rubberized concrete, Polymer concrete, Geopolymer concrete, Gypsum concrete, Foamed concrete, and so forth.

In this construction article we are presenting about Vacuum concrete, its method and also its advantages.

In 1935, vacuum processed concrete first invented in USA by Billner.

Vacuum concrete is the type of concrete which excludes the excess water to enhance the strength of concrete. The excessive water is removed by the use of vacuum mats which is connected to a vacuum pump.

Method and Equipments necessary for vacuum concrete:

As we discussed earlier, the main purpose of the method is to remove extra water from concrete body using vacuum dewatering. As a consequence of dewatering, there is a noticeable deduction in effective water-cement ratio and the performance of concrete upgrades extremely. The enhancement seems more on the surface where it is mostly necessary.

Generally, four components are required in this concrete process. They are:

1. Vacuum pump

2. Water separator

3. Filtering pad

4. Screed board vibrator

Benefits

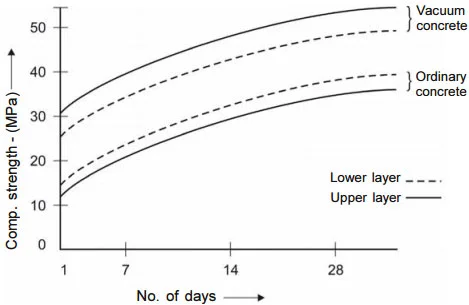

- Enhance the compressive and tensile strength

- Make concrete resistance to abrasion and impact

- Make concrete resistance to the freeze-thaw

- Lessen the shrinkage

- Make lower permeability and greater durability

Source : civiltoday.com