The term stirrups refer to the lateral reinforcement in the flexures members. Moreover, the term ties to the lateral reinforcement in the vertical compression members.

There are various types of stirrups depending on the nature of construction.

Some of them can be:

i. Single legged

ii. Double legged

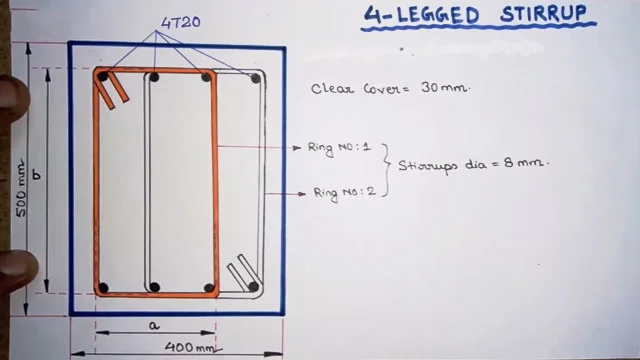

iii. Four-legged

iv. Six-legged stirrups

Based on the code you are using, the spacing is generally limited to a minimum spacing between each set of the stirrups. Furthermore, you are limited in the size of the re-bar you can practically bend into stirrups. Taking all these things into consideration, you can have two-legged stirrups, four-legged stirrups, six-legged, and many more, to increase the area of the shear reinforcement at each set of the stirrups to match your requirements. You can also have an odd number of legs if you use the hooks.

I. In the uniaxial compression test of the concrete, after reaching the ultimate load failure of concrete occurs where the major cracks line up in the vertical direction as well as the concrete cube would be split up. The development of the vertical cracks involves the expansion of concrete in the lateral directions. When the concrete is confined in the lateral directions, it was generally observed that the formation of the vertical cracks can be hindered. As a result, the concrete strength is increased.

II. The above-mentioned theory is used in the design of the bridge columns. Steel stirrups are installed around a vertical main reinforcement. It also helps to avoid the lateral deformation of the interior concrete core as a result the strength of the concrete column is increased.

III. Moreover, open stirrups are provided mainly to resist the shear forces in the concrete beams as well as they are applied in the locations in which the effect of torsion is insignificant. U-shaped stirrups are usually placed in the tension side of the concrete beams in which the shear cracks would occur.

IV. The concrete beams vary in depth. The deeper the beam, the more sheer its capacity would be. While the depth is inadequate, steel stirrups should be added for increasing the shear capacity of the beam. These are usually one piece of steel that is bent into the shape of a rectangle. Often small-diameter steel is used. The stirrup generally wraps around the bottom as well as top bars of the beams.

V. Most often the stirrup is not prefabricated. And the installer tries to make the stirrup in the field when the horizontal bars are already in place. It is usually obvious as the stirrup is constructed from two pieces with inadequate lap splice. This is much easier as well as efficient to install a stirrup at the time when the horizontal reinforcement is being installed.

These are the basic things that you need to do to accomplish the task.