BlogWhy To Choose Civil Engineering As Your Career?A time comes in your life when you need to take the toughest (to someone, it is the easiest) decision…

BlogWhy To Choose Civil Engineering As Your Career?A time comes in your life when you need to take the toughest (to someone, it is the easiest) decision… Blog6 Types of Columns That Are Essential for Building ConstructionColumn is a vertical structure, which carries loads chiefly in compression. It can transfer loads from a ceiling, roof slab,…

Blog6 Types of Columns That Are Essential for Building ConstructionColumn is a vertical structure, which carries loads chiefly in compression. It can transfer loads from a ceiling, roof slab,…

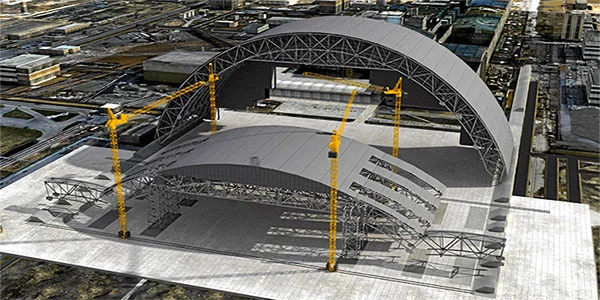

Construction

view all-

Building Construction Manual

23rd April, 2019 -

-

How Do You Hire Construction Management Company

23rd April, 2019

-

Building Construction Manual

23rd April, 2019 -

-

How Do You Hire Construction Management Company

23rd April, 2019

Engineering

view all-

A Comprehensive Guide to Cement Waterproofing: Techniques and Benefits

3rd January, 2023Waterproofing is one of the essential components of any construction project, particularly for structures that are exposed to moisture or water. Cement waterproofing is a [...]

-

Why To Choose Civil Engineering As Your Career?

22nd March, 2021A time comes in your life when you need to take the toughest (to someone, it is the easiest) decision of life. Thinking what it is? It is nothing but the field that you want [...]

-

4 Main Kinds of Access Platforms and their Usage

10th April, 2022Knowing the different kinds of access platforms is important in planning the efficiency of your operational workflow. It will help you choose the best one that will suit [...]

-

Design Tips & Tricks That Will Benefit Any Contractor

17th April, 2021Building design and construction are under constant pressure to generate something unique under shorter time frames and smaller budgets. Additionally, constant code changes [...]

Tutorials

view allA Comprehensive Guide to Cement Waterproofing: Techniques and Benefits

Waterproofing is one of the essential components of any construction project, particularly for structures that are exposed to moisture or water. Cement waterproofing is a [...]

-

10 Superior Solutions To Roof maintenance

16th May, 2019 -

How To Keep Your Construction Worksite Safe

16th May, 2019 -

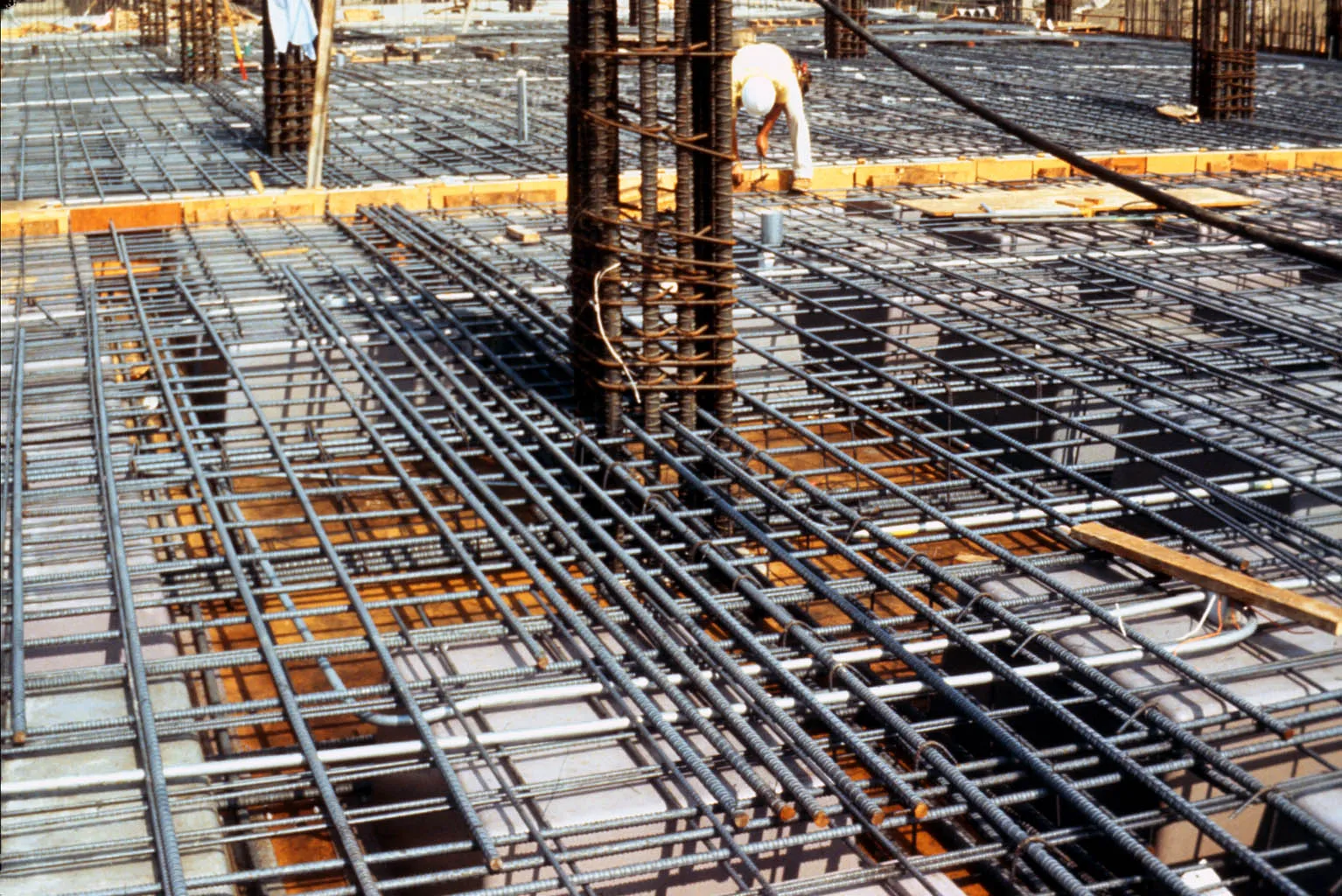

Individual Reinforcement In Civil Engineering

16th May, 2019 -

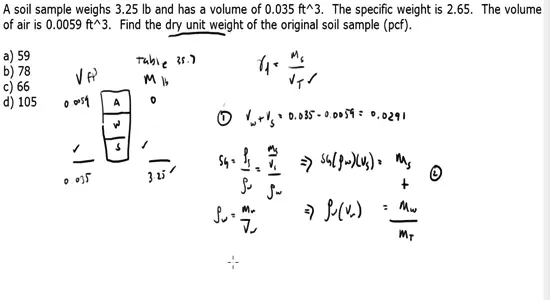

How To Solve Soil Phase Diagram for Dry Density

16th May, 2019

Popular Videos

Stories for you

A Comprehensive Guide to Cement Waterproofing: Techniques and Benefits

Waterproofing is one of the essential components of any construction…

Why To Choose Civil Engineering As Your Career?

A time comes in your life when you need to…

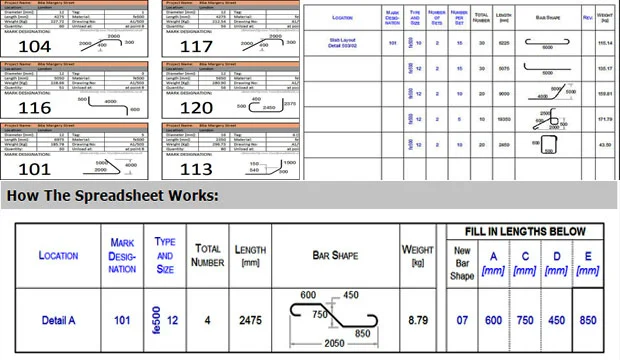

Bar Bending Schedule Spreadsheet – Free Download

A brand new bar bending schedule spreadsheet having some great…

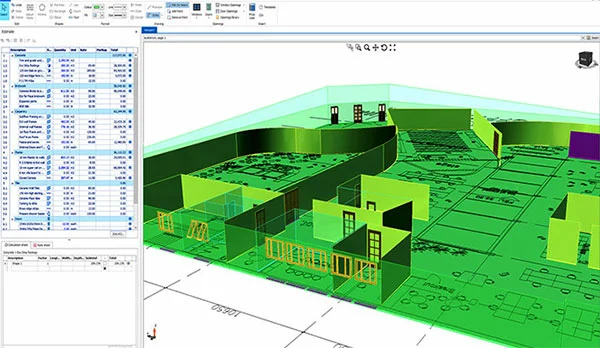

Download Structural Steel Estimating Takeoff Sheet And Learn To Use This Template

This structural steel template is really helpful for structural engineers…

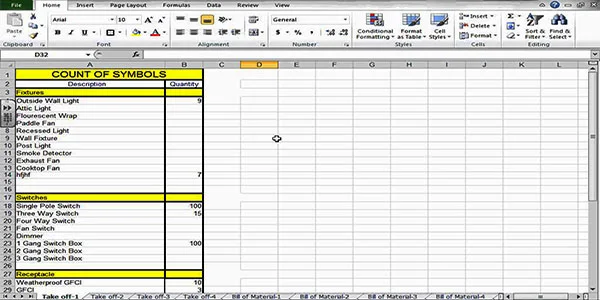

Electrical Estimating Take Off Sheet

Electrical estimating take off sheets help electrical contractors with the…

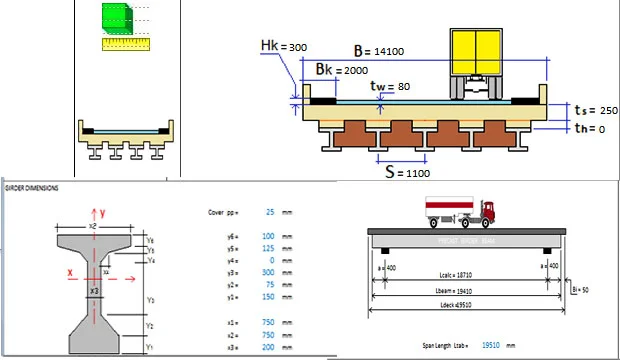

Download Free Bridge Design And Analysis Spreadsheets Essential For Bridge Engineering

There are many types of construction available in the construction…

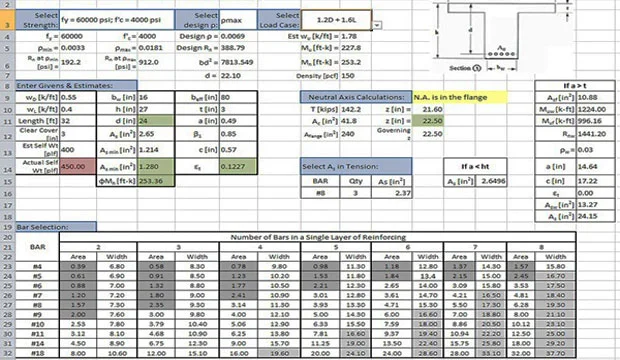

Download And Access Concrete Design Excel Sheets

Are you facing any sort of trouble to design structural…

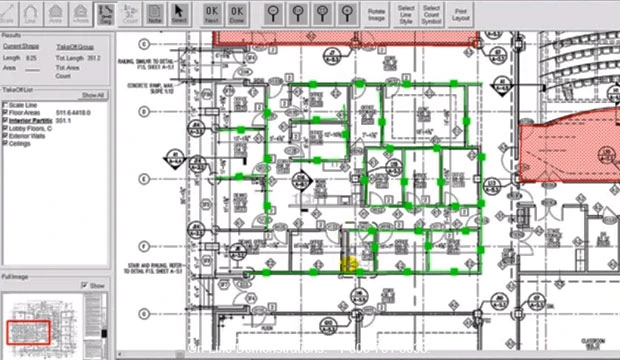

PDF Takeoff for All Building Trades useful for Construction Estimator

A good construction project needs an accurate estimation of construction materials and…

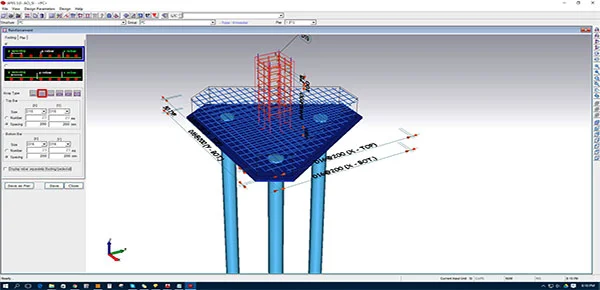

Advanced AFES Foundation Design Software For Effective In Construction Field

Establishment outline is generally done physically this involving vast labor…

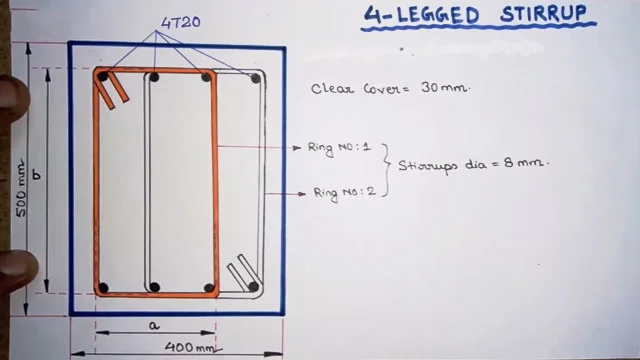

How To Calculate The Cutting Length Of 4-Legged Stirrups

The term stirrups refer to the lateral reinforcement in the…

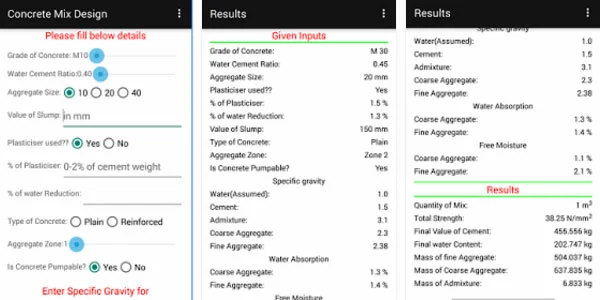

Concrete Mix Design App And Its Usage

Concrete Mix Design app is very beneficial for all the…

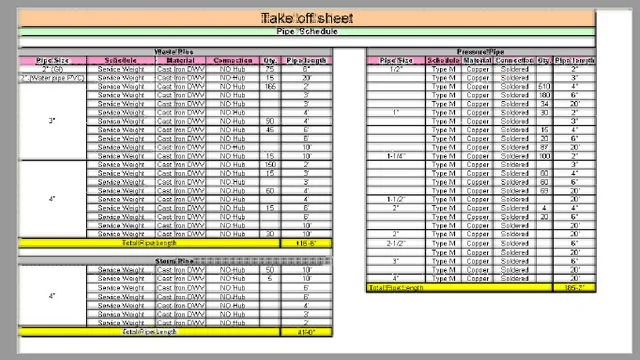

Free Download Of Plumbing Takeoff Sheet In PDF Format

To perform plumbing work accurately good number of knowledge and…